In-Mold Decorations: Integrating Style and Manufacturing Excellence

Mastering In-Mold Decorations: Strategies, Patterns, and Best Practices for Ideal Outcomes

In the world of manufacturing, the art of in-mold decors stands as an essential aspect of product layout and production. As sectors constantly look for innovative methods to enhance visual allure and functionality, grasping the details of in-mold designs has actually arised as a vital capability. From selecting the ideal materials to integrating sophisticated design patterns, the trip in the direction of achieving ideal cause this domain name is multifaceted. By delving right into the approaches, trends, and finest techniques that underpin effective in-mold decoration processes, services can open a world of possibilities that not just raise the visual attraction of their products however additionally streamline production effectiveness and bolster consumer interaction.

Material Selection

Product selection is a critical element of mastering in-mold designs, as it directly affects the quality and longevity of the final item. When selecting products for in-mold decorations, it is crucial to think about variables such as compatibility with the molding process, the wanted aesthetic end result, and the environmental problems the item will encounter.

Furthermore, the chosen product must have good bond homes to make certain that the design sticks firmly to the substratum during the molding process. Attachment between the design and the product is essential for protecting against delamination and making certain resilient aesthetic allure. Additionally, materials with high warm resistance are favored for in-mold decorations, particularly for items that will certainly be revealed to raised temperatures during their lifecycle. By very carefully picking the appropriate material for in-mold designs, makers can boost the overall quality and sturdiness of their items, satisfying the assumptions of both customers and end-users.

Layout Technology

A crucial consider progressing the area of in-mold designs is the constant exploration and application of design innovation techniques. Layout technology plays a crucial duty in improving the aesthetic charm, functionality, and overall top quality of items produced using in-mold decor procedures. By integrating ingenious design components, makers can separate their products in the marketplace, draw in customers, and stay ahead of competitors.

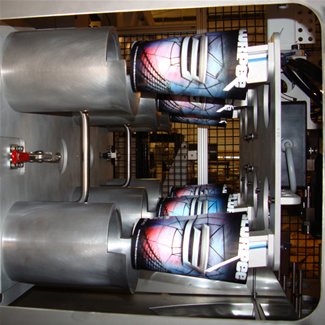

Among the key elements of layout technology in in-mold decorations is the combination of elaborate patterns, appearances, and graphics that were previously challenging to accomplish with standard design methods. Advanced modern technologies such as 3D printing and digital style devices make it possible for designers to create complex and detailed styles that can be effortlessly transferred onto molded parts. In addition, making use of vibrant colors, metal surfaces, and special impacts like gloss or matte textures can even more boost the visual charm of in-mold enhanced products.

In addition, design development expands beyond looks to encompass practical improvements such as ergonomic forms, integrated functions, and personalized elements that deal with particular customer needs. By welcoming layout advancement, manufacturers can open brand-new possibilities for product, personalization, and imagination differentiation in the affordable landscape of in-mold designs.

Manufacturing Performance

Effective manufacturing processes are necessary for converting the innovative designs created in the area of in-mold decorations into top quality finished products that fulfill market needs and customer expectations. In the realm of in-mold decors, production efficiency incorporates different crucial aspects that add to the general success of the manufacturing procedure.

Automation not only speeds up the manufacturing process however additionally improves accuracy and repeatability, leading to a much more consistent and top notch end item. In general, an all natural approach to production effectiveness is vital in taking full advantage of the possibility of in-mold decor strategies and accomplishing ideal results in the competitive market landscape.

Quality Assurance Actions

What are the key techniques for ensuring strict high quality control actions in the realm of in-mold designs? Quality control actions are vital in in-mold decor processes to ensure the manufacturing of remarkable and top notch completed products. One important technique is the application of rigorous inspection protocols at every phase of the production procedure. This entails carrying out comprehensive visual examinations, dimensional checks, and color consistency analyses to determine any issues or variances beforehand.

Utilizing innovative technologies such as computerized inspection systems can likewise boost the quality assurance procedure by providing precise and reliable data for evaluation. These systems can identify flaws that might be missed out on by manual assessments, therefore improving general item top quality and consistency.

Routine training and growth programs for employees entailed in the in-mold decoration process can likewise add to preserving click here to read high-quality requirements. By enlightening personnel on best practices, high quality assumptions, and the relevance of focus to information, companies can promote a society of quality consciousness throughout the organization.

Customer Allure

To enhance the marketability of in-mold design items, providing and understanding to consumer preferences play an important duty in determining their appeal and success. Consumer charm in in-mold decors is influenced by different variables, consisting of design looks, shade selections, sturdiness, and general performance. Consumers are progressively seeking customized and special products that reflect their originality and style. As a result, providing personalization choices such as individualized styles, color variations, and textural components can dramatically improve the appeal of in-mold decoration items.

Final Thought

In-mold designs provide a versatile and efficient method to improve product aesthetic appeals. Grasping in-mold decorations requires a holistic approach that takes into consideration all facets of the manufacturing procedure to make certain success.

In the world of production, the art of in-mold designs stands as a critical aspect of item design and manufacturing. Style technology plays an important function in boosting the visual charm, performance, and overall top quality of items made using in-mold decor processes.One of the vital facets more tips here of style development in in-mold decors is the assimilation of elaborate patterns, appearances, and graphics that were previously testing to accomplish with typical design approaches.Effective manufacturing processes are crucial for converting the cutting-edge styles created in the field of in-mold designs right into top notch finished products that fulfill market demands and consumer assumptions. Providing customization choices such as tailored designs, color variants, and textural components can considerably boost the appeal of in-mold design items.